Development report

|

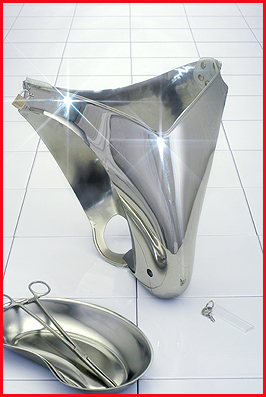

Once upon a time we received an invitation to a castle party. I created a chrome plated steel corset for my wife to wear to this event. Clients who had already worn self-made or purchased versions of a chastity belt shared their experiences with me. Those were not only positive, it turned out that there were several requirements to be met in order to ensure a pleasurable wearability of a chastity belt: |

1.) It should be wearable over long time without causing any physical problems

2.) It should be invisible if worn under regular clothes

3.) It should guarantee maximum comfort, especially around the testicles because painful experiences have been made with the models available on the market so far.

Additionally, the testicle area should shield the testicles from any contact with metal parts because the cooling sensation would result in the urge to urinate.

4.) It goes without saying that using the toilet should be possible in locked up mode

5.) The chastity belt should be flexible enough to accommodate possible weight fluctuation of the user.

I told my clients that I was up for the challenge and asked them to check back with me again in about three months.

First, I produced a replica of the male body and started to work on a metal cover for the genitals trying to make it as scanty as possible. Then I took a step back to lean against my anvil. Cross-armed I contemplated my work. I realized that the lady would see her man exactly from this perspective and it struck me that the list of requirements was lacking another crucial point:

6.) The belt had to be aesthetically appealing making the man look like a stud (and not like a fool).

I decided for a continuous slip shape to cover the whole area instead of a shape with a telling bulge that would be visible under regular pants (referring to top 2). I used the entire heights of the slip to slightly increase the up-arching toward the genital area. Thus, it does not bulk up in the front but slightly toward the bottom making it less noticeable under every day clothing.

Sitting in the car or in an office chair is no problem, only if you sit on a hard bench the belt will slightly move upward forcing the user to sit rather straight.

From my customers I learned about a common problem they had with chastity belts when the rear side of the belt was made from metal strips or chains. Once the wearer lies down and the stomach flattens he is able to pull out his penis to the side by lifting the front part of the belt. This originates from the belt being too flexible and the contact area on the buttocks being too small, consequently allowing the strip to sink into the yielding flesh.

This information supported my idea of a slip form even more. With a three-dimensional rear-side part, which of course would have to be made-to-measure for every customer, the belt would not move causing a gap in the front, hence the genitals will stay in place safely.

Admittedly, trimming chains and metal strips is much easier done than forging a unique three-dimensional metal sheet for each customer, but safety should be one key aspect of the chastity belt.

The slip form chastity belt is to be fastened at the hips. The hip sheets are made separately providing for adjustments due to possible weight fluctuation (referring to top 5 of the requirements list).

It took me three month to create a modern and rather futuristic looking model. However, it was not yet ready to wear. The metal edges running perpendicular to the body surface in the crotch still resulted in serious pressure marks while walking or sitting. I spent another month trying to solve the problem but to no avail.

I needed a flexible edge solution, which would adapt to each movement of the wearer without suppressing the blood flow in the lower extremities. I was searching for a material with silicone properties. Due to the poor heat-conducting characteristic the material would also be perfect for the encasement of the testicles. Now, that I call killing two birds with one stone and top 3 of the list (maximum comfort around the testicles) is taken care of.

|

Another month went by with further experiments. The required material should not release any harmful substances like plasticizers or solvents and should not cause skin irritations or contact allergies. Finally, I was able to deliver to the first impatiently waiting customers. Naturally, the chastity belt was still in its infancy; however, I was able to continually improve it based on the feedback of my customers. E.g., at first the belt design was cut too high. A more sportive and lower cut form increased the comfortability tremendously. Also, the silicone turned out to be the perfect choice of material. |

Cleaning

In order to fulfill top 4 of the requirements going to the toilet should be possible leaving the belt in locked position. Accordingly, there is an opening for drainage at the lowest point of the belt. Unfortunately, that was where another childhood's disease became obvious. An erect penis would block the opening and cause the water to rise inside the chamber making unlocking and cleaning the belt inevitable.

Now an added reservoir will keep the opening free from obstruction and lets me check off top 4.

The steel edges around the butt hole are exposed to stresses and strains when sitting since the sheet is weakened due to the big opening. In order to avoid any distortion of the material I added rounded reinforcement to the edge.

There was one thing that had not occurred to me so far. The reason for wearing a chastity belt is that you are not able to touch yourself. This requirement was fulfilled perfectly, to an extend that the wearer was not even able to clean himself. After two or three days you could tell from the smell...!

This problem seemed unsolvable. While taking a shower I remembered the Apollo 8 landing on the moon. An astronaut had shared his feelings about floating in space wearing his space suit and merely being connected to the Apollo through a kind of umbilical cord. He recalled being surrounded by absolute silence. The only thing he heard was the buzzing sound of the circulation pump that constantly flushed his underwear with warm water. Apparently, the NASA engineers did face the same challenges I did.

The astronaut, too, was not able to use the toilet during his mission, he was not even able to take of his space suit. Nevertheless, body hygiene had to be ensured.That led me to the idea of developing an internal piping system that would flush the penis by injecting warm water through little nozzles with the help of an adapted syringe. After two weeks this problem was solved at last. The maximum wearing time was now to be extended infinitely, depending on the motivation of the user (see top 1 – longterm wearability). |

|

Lock

Popular request inspired my final improvement to the already matured and fully functional model. Customers found the chastity belt still not to be completely escape-proof. The exposed shackle of the padlock would not withstand the use of a bolt cutter, they requested an integrated lock.

Intending to simplify the issue I obtained magnetic locks like the ones being used in hospitals to protect seizure patients by physically restraining them from hurting themselves . Easy to use, no keys required – simply brilliant. The only disadvantage was that literally any magnet could open the lock.

What a shame! So back to the drawing board. On May 5 th , 2000 I finally held the first chastity belt with integrated lock in my hands.

Customers who already owned the previous version of the chastity belt with external locks are welcome to have it upgraded.

Four years later (November 2004)

During this period of time I was able to learn plenty from the long-term experiences of my customers, who wore the belt day in, day out. Some of those customers reported that the mounting of the hinge in the crotch, which is carried out by chrome-plated brass rivets, weakens after time.

The challenge with the riveting

The analysis of the problem in my workshop showed that indeed the quality of the rivets deteriorated over time. Upon investigation I discovered that the supplier of my rivets had maximized his profit by switching to a cheaper manufacturer from abroad – like in most cases at the expense of quality. This seemed to be a general tendency with all potential suppliers. Apparently, it was almost impossible to find rust-proof double cap rivets with equally flat caps on both sides which were strong enough to withstand the strong shear-force that occurs at this connection.

Of course there would be other ways of joining the hinge to the belt. Welding, e.g., would make the use of rivets obsolete. However, in the longer term this was not an option because it would not accommodate any potential weight fluctuation of the customer.

A solution came in sight when I abandoned the idea of fixing the problem with readymade rivets.

Open-minded I rummaged in the shelves of my favorite wholesale of industrial supplies and found a kind of rivet that was originally intended for another purpose. |

|

Separating the chambers

Another issue was that the ergonomics of the penis tube should be further improved to induce a feeling of comfortability and pleasure. Because the penis tube has a smooth, soft, and flexible surface, and applying a lubricant makes it feel warm and slippery, the wearer has the sensation of being stuck and surrounded by something. The lovers of tightness enjoy the counter-pressure that arises in the tube once the penis swells.

To further increase the pleasure for the user I developed a new model that would envelope the penis starting from the root. The advantage is that the testicles and the penis are separated even more causing a feeling of being stuck inside even further and deeper.

From the very beginning I stressed the importance of a standardized socket so that even the oldest model of the chastity belt could be upgraded with this chamber.

Another year later (August 2005)

I am now introducing you to a new product development which is not so new after all. Years ago, I have already constructed it once upon special request of a noble lady for her personal slave.

Bottom bar

What used to be a unique piece years ago was now going to go be manufactured in series. First, I concentrated on the bottom opening. A small bar would divide the round into two halves making it impossible for the user to insert a dildo for his own pleasure (ref. Top 8). Furthermore, should the dominant lady choose so, the bar could be fitted with a dildo that could not be removed by the wearer. My first construction was rather simple, I just welded the bar on.

However, I had a more elegant solution in mind. The bar should be easily fitted. But, once the belt was closed, it should not be removable anymore. Naturally, the bar had to cross the bottom hole vertically to ensure that the optionally added dildo could slide back and forth to accommodate the wearer's movements. It goes without saying that older versions of the chastity belt should be upgradeable with this feature.

| I was already brooding over a solution for three days when, during some time off on my motorcycle, the most elegant and genius solution suddenly hit me. I could not get home fast enough to get to work because I had to see my vision turned into a high gloss polished piece. |

|

At three o'clock at night the mission was accomplished. Another two hours went by admiring and enjoying this perfect solution come true. It was five o'clock in the morning when I finally went to bed and only than I realized that I was still in my motorcycle pants and boots in which I had apparently been standing at the blacksmith's fire.

Dildo

Based on this new found solution I was now able to get to work on topic 8 – the manufacturing of dildos. Naturally, I first thought of stainless steel. However, that would have the disadvantage of a rather high weight which would drag the belt down and increase the pressure on the hip bones.

Because of that I decided for another appealing material, acrylic glass.

On my lathe I produced the first prototype and gradually approached the ideal shape. One of my customers, a dildo lover, volunteered as guinea pig and tested various shapes in combination with his chastity belt.

|

The conclusion was that the dildo's head shape had no sensual effect once it passed the anal sphincter. On the opposite, the end of the dildo was permanently enclosed by the muscle ensuring that the shape was constantly felt. |

One of the most interesting shapes let the dildo end rather abruptly with a small radius. This would not be anything new but in combination with the tight fitting chastity belt the dildo stayed fixed in a deep position. And if the end of the dildo was positioned in a way that the rounded end was situated in the middle of the sphincter the dildo would be moved in and out in response to body movement.

Other dildos that are held in place by crotch straps or something similar would leave the anal sphincter either opened or closed the whole time. With my innovation, however, the anal sphincter would constantly open and close, consequently causing a feeling of arousal.

My test person, who had already enjoyed various experiences in this area, was totally enthusiastic about this new sensation.

Electric dildo

I wanted to incorporate the findings from the newly developed dildo shape into the construction of a stimulation current dildo. With stimulation current the position of the contact area in connection with current strength and frequency is essential. With stimulation current dildos two kinds of sensual experience can be distinguished. If the contact area is located towards the top of the dildo, meaning deeper inside the body, the sensation is that of a pulsation throughout the abdomen.

However, if the contact area is at the end of the dildo, thus touching the anal sphincter, the feeling is more punctuated. And because the dildo is not just resting inside the body but – being fitted with the extra sensation head – is passing the anal sphincter with every body movement the experience is quite sensational.

| It would be even better if the dildo would offer the possibility to switch between both kinds of experience – the one responding to body movement and the one where the dildo stays in a fixed position. I had set my mind on combining all four aspects in one dildo so my customers could enjoy the full range of sensations with one single purchase. |

|

First, I paid my favorite wholesale of industrial supplies a visit and got me a selection of plugs and sockets as well as some flexible silicone cable. I transferred their measurements to the drawing board and started conceptualizing. After one day's work I had an unusual construction on paper - with precise measurements ready to be manufactured with the lathe.

The six-piece plug-and-screw construction is a speciality that allows the user to individually assemble the dildo according to his taste by connecting the desired parts and securing them with a stainless steel eye bolt.

Electrical chamber with cable

Pleased with the result I was now ready to move on to top 9, the last topic on the list of desirable requirements of the chastity belt: to fit the penis tube with electrical stimulation contacts. Fortunately, right in time to tackle this challenge I met a customer who was willing to serve as a test person. He stuck thin aluminum strips to his penis and charged them – one by one - with electricity. He found out that the contact area is best sized 4 cm (about 1 ½ inches) wide and 1 cm (3/8 inch) high and located 1 cm below the glans.

This enables the user, depending on the wavelength controlled by a special program of the Two-channel-TENS-device, to either relish a lustful orgasm or experience a painful punishment.

Considering this and the fact that the device would be implemented in a chastity belt the logical consequence could only be to place the connecting plug inside the belt to prevent the wearer from operating the electrical device and relieving himself.

The power of control lies with the key mistress, it is up to her to exert lust and pain over her submissive.

Since the contact area has to be curved three-dimensionally, I created it from precious metal and carefully placed the cables alongside the prototype, thus ensuring that they would tolerate the movements of the finalized chamber.

I handed the so equipped prototype over to my willing customer to get his feedback on further improvements. We then went into more detailed enhancements. Prototype No.2 got fitted with a brass sleeve which encased the spigot and therefore guaranteed the back-flow to the negative pole (the entire chastity belt). For the penis tube contact area I chose a flexible surface electrode.

In order to further enhance the sensation on the penis it is recommended to apply ultrasound gel to the chamber. Above the electrode, additionally installed channels for cleaning fan out to help with the even distribution of the gel. The advantage is that the ultrasound gel, which is thinner compared to regular electrode gel, can be injected directly between the penis and the electrode with a special syringe (that is included in the stimulation electrical chamber set). Again, this prototype No.2 was tested by my trusted customer.

Lying on his back and sucking in his stomach extremely he was able to work his way toward the plug and simply pull it out of the socket. Even worse, he was able – although with slightly more effort – to plug it back in!

What a bummer! The implanted plug adaptors facing the belly had turned out really beautifully.

On to prototype No.3. Here I chose to install the socket on the opposite side of the chamber which connects to the metal. This version could not be outsmarted by the test person. The only disadvantage was that the wiring, that needed to be embedded in silicone inside the chamber, was now much more difficult to place.

|

When it came to choosing the right electrical TENS device from a rather large assortment I opted for a two-channel variation. With 80 mA this was powerful enough and could be comfortably operated by the mistress. Furthermore it was able to simultaneously but independently charge the dildo and the penis tube with electricity. |

Would the mistress want to use her man as a slave for her own satisfaction, e.g. for licking, she would need a big enough display with easily manipulable switches to concentrate on her lust while controlling the slave's licking frequency (hz) and -intensity (mA).

To increase the pleasure even more, I constructed a plug-in holder to be added on to the sex chair (see Deck 5, devices catalogue, left square) so the lady could glance at the TENS-device easily while operating it with one hand. This SM device is especially suitable for servant games. The licking slave's hands can be tied up while he is attending to his work kneeling in submissive position on the knee pad.

I wanted to start outfitting the chastity belt with a wireless remote control not until size and costs of the devices reached an acceptable level. It seems the time has come to get to work.

Naturally, in my imagination the receiver was to be placed inside the chastity belt. The right location basically presented itself. It should be inside the silicone chamber for the following reasons:

Everybody, who already owned any one of my chastity belts would be able to replace the regular chamber with the electrical device without having to send the belt to me for upgrading. Thus, a new game level was now only a phone call away. For this reason I have previously standardized all connection areas.

Furthermore, no additional box of any kind would have to be added to the outside of the belt making it difficult to hide under every day clothing. Last but not least the elegant design of the belt would be maintained.

Radio receiver chamber

First, I started with the selection of a remote control. I asked every main supplier in the market to send me a sample of their device. The final decision for the best suitable device was rather quick. My criteria were power, size and a handy design. Innotek from the USA made the race.

The next challenge was to place the receiver inside the chamber in a way that it

a) could not be removed in locked-up position,

b) could be taken out for charging,

c) would reliably connect when plugged in,

d) could even receive a TENS-device once the receiver is taken out and replaced by a special adapter plug.

I began by building a kind of wire cage around the outside of the silicone chamber with clear space wide enough to enable me to get my fingers through to the inside of the model. The wire cage needs to open in order to allow for a variety of genital positive models to be placed and fastened inside.

I now placed the receiver inside the cage which – due to its shape - already limited my placement options. I assumed that I could determine the exact position with my fingers from the outside once the cage was closed. So much for theory. Fact was that the cage was not even closable in the first place. The receiver was still too large.

One of the original requirements of the chastity belt was that it should be invisible under every day clothes. This is the reason why I built it as small as possible. Now, a few more millimeters would have been much appreciated!

I took the receiver out of the cage and carefully placed it on the cast iron table. I then started the belt saw and pushed the receiver including all its inner life lengthwise through the saw cutting it in halves. Now I got a good look inside and immediately detected some unnecessary spaces.

O.k., I thought to myself, those corners need to go.

I then ordered a new receiver and milled off the redundant parts from the casing up to a clear defined line carefully making sure not to compromise the waterproof properties. With this new refined size I was finally able to close the wire model.

In order to fulfill point a) the receiver should not be removable from the side of the silicone chamber that is facing the belly. Instead, it should be taken out from the side that is facing the metal inside of the chastity belt. I had already learned my lessons when placing the plug for the TENS-device.

I packed my motorbike case with the following: the three-dimensional cage including the receiver, caliper, pencils, eraser, drawing board, file, etc. - just the things you need for spending a summer day at the lake.

Once I arrived at my favorite quarry pond I hung my hammock between two pine trees, placed my motorbike case in reach, stepped out of the riding gear and flung myself into the hammock.

On my way here I had already thought about how to kill two birds with one stone, with the birds being a) the receiver should not be removable in locked-up position, but b) could be taken out for charging. To make the unauthorized removal of the receiver even more difficult I came to think about two undercut edges built from the flexible silicone of the chamber that would embrace the receiver to secure its position and guarantee contact.

Relaxing in my hammock I gazed at the wire cage and tried to imagine the missing cable loom as a closed circuit. I realized that no matter what kind of plug-in I would choose to connect the receiver with the cable loom, I would have to build a new mould for the chamber that would include an assembly window to allow for placing the cable loom.

(Short explanation: In order to produce a cast from silicone the mould needs to consist of two halves that can be separated to release the hardened cast.)

My problem was that because of top a) the receiver belonged to the upper half of the mold while the tube contacts were located in the bottom half. Both parts of the form would have to be screwed together in order to connect the contacts. An assembly window would be the only way to make this possible.

Next, I had to tackle the plug contacts from the receiver to the cable loom. My idea was that copper strands, firmly vulcanized into electrically conductive silicone and shaped into the form of a coupling, should accept the threaded pin of the receiver. It took me about two month to realize the idea. And to learn that it has taken me down a dead-end street!

The problem was, that regardless which supplier I chose, my conductive silicone would develop cracks only hours after being injected into my especially manufactured mould. Tempering or applying release lacquer did not change the outcome.

The industry had developed this material for superficial application intended to counter-act electrostatic charge in the range of a fraction of a millimeter. Other materials in liquid form were unavailable in the market.

Well then, I opted for a safe and time-tested bonding method.

From brass wire I bent clasps to embrace the receiver's contacts making sure that they were outfitted with an large enough surface to allow for interlocking and thus bonding with the silicone. In order to determine the varying lengths of the silicone cable which then had to be welded to the clasps, I first had to construct a new mould with assembly window. |

|

About three weeks later the new mould was ready to go. With the help of curved long-nose pliers I was finally able to reach into the assembly window of the closed mould to snap the brass clasps in place and determine the cable lengths.

That was where the next problem was awaiting me. The highly flexible silicone cables seemed to have a mind of their own. They either lay on the surface of the outer mould, or at the positive core of the testicle chamber, or they attached themselves to the thin channels of the cleaning nozzles.

If I would be dealing with a rather stiff copper-wire cable it could have been bended in a way that it would hold its position unassisted. That would have made things a lot easier. However, this was not an option. On the contrary, due to the flexibility of the silicone chamber the stiff cable inside would break sooner or later.

Somehow I had to come up with a special spacer which would force the flexible silicone cables into the desired shape.

Meanwhile we were running out of space inside the chamber and only my wife with her lean fingers was able to work inside.

Ever so slightly we now closed the assembly window of the mold and pumped in the slow flowing silicone with high pressure until the material reached the marks on the risers.

After 24 hours we pulled all locking pins out of the mould and opened it.

Prototype No.1 was born and scrap just the same! The spacers had not prevented the silicone cable from moving to the surface of the cast. Either the high pressure or the thick liquid were to blame that the cables were visible from the outside – a tell tale sign that they were not sufficiently embedded.

The second shortcoming was that the brass clasps were not covered deeply enough in silicone either, leading to cracks when the receiver is being pulled out.

I worked on the necessary improvements and with prototype No.4 I finally had a grip on the issue. The key was to mix the two-components silicone material under low temperature.

This would prolong the pot life about 15 minutes allowing me to reduce the pressure and thus the injection rate significantly.

Prototype No.4 taught me that the serial manufacturing of electrical current chambers had to strictly stick to a specific time- and temperature specification.

Now type No.4 was ready to be tested in real life.

During a three-week trial period the customer and his wife put it through their paces.

It turned out that the chamber not only stood up to my expectations but even surpassed them. The lady's pleasure was tremendously increased by the fact that she now was not only the owner of a key but the mistress of a remote control. With the remote control that could be easily carried along in her handbag all differences and discussions would be decided in her favor.

The certainty of owning the absolute power influenced the whole game in a never before experienced way. Sometimes the mistress was angry about his immediate obedience because that would keep her from pressing the red button on the remote.

He, on the opposite, would have wanted his mistress to be more harsh to let him experience his submissive position even stronger.

With the electrical shock on his penis he felt increasingly powerless and experienced the authority and control of his mistress even in ordinary situations like groceries shopping. The radio receiver chamber was now ready to go into serial manufacturing.

|

|

Another few weeks later I had another idea concerning the feeding of the electrical impulse into the penis electrode. The idea was to supply the electrical impulse from both sides instead of one.

If I would succeed in modifying the flexible surface electrodes in a way that it would achieve a certain electric resistance (Ohm per cm) the advantage would be that the impulse, coming from both sides, would be slowly weakened and produce an enhanced sensation to the stimulated areas at the penis – those that are responsible for causing an orgasm.

I stopped the series and asked my wife Mona to console the customers until later.

The initial idea concerning the resistance value I derived from the fact that the suppliers of the rubber electrodes would state different resistance values. I ordered samples for further experimentation.

The result was that I needed an high-ohm electrode. This would have to be manufactured especially for us which the supplier agreed to do on the basis of a higher purchase quantity. I was obsessed with my idea and took the risk by buying electrodes for years to come.

Meanwhile, customers who had already ordered a chastity belt with radio receiver chamber, grew rather impatient since I had already passed the delivery date.

Too bad that I had another idea! I wanted to slightly decrease the size of the tube at the area where the penis electrode would be located. The execution of this almost drove me out of my mind - and my waiting customers as well.

After month of research and development we were able to proceed with the serial production of the radio receiver chamber. Next, I wanted to work on the plug adapter which should optionally connect the radio receiver chamber with the TENS-device turning it into a TENS chamber. But the lined up orders would not let me.

This is going to be an increasingly big dilemma for me. On one hand we are booking an increasing number of orders with a simultaneously growing product range on the other hand.

There are only two solutions. You can concentrate on the on-time delivery leading to a temporarily satisfied customer. A few months later though the same product will be available in an improved quality and the customer will be put out.

In the second approach I would let the delivery date pass in favor of another idea that lets me further perfect the product. In this case the customer is unsatisfied because of the delay. If only he could see that it is worth his while all would be good.

However, you know the saying if wishes were horses beggars would ride.

I personally think that the second way is right for the customer although he might not be able to see it right away.

Addendum regarding the radio receiver chamber

A couple has shared a story with me that they themselves had experienced. They have been at the movies and the husband - totally absorbed by the film - stuffed himself with popcorn. He had no eye for his lady even though she made an effort to look extraordinarily pretty. Naturally, she was not pleased with his lack of attention.

|

Venting her displeasure she took the remote control and pressed the button. Nothing happened! Of course the couple reflected on what had just happened. The key to the mystery was not a dying battery but the fact that due to the thrilling film plot his penis has gotten smaller and lost contact with the electrode. |

I build a new receiver chamber placing an additional, narrow contact higher up. This would protect the customer from unwanted surprises in the future. This improvement is included in the serial production.